Primary circuit components inspections

STAGING INSTANCE

For more than 40 years, Intercontrôle has been a leading player in the in-service inspection of safety-critical components of nuclear reactors.

On average, Intercontrôle conducts 100 interventions per year on the different components of the primary circuits of nuclear reactors.

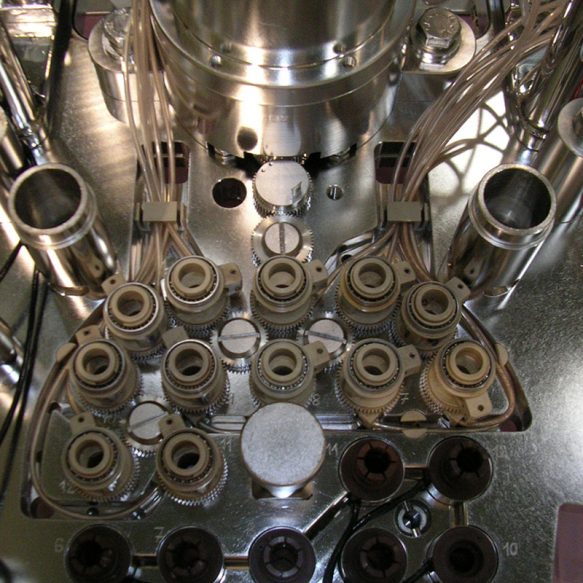

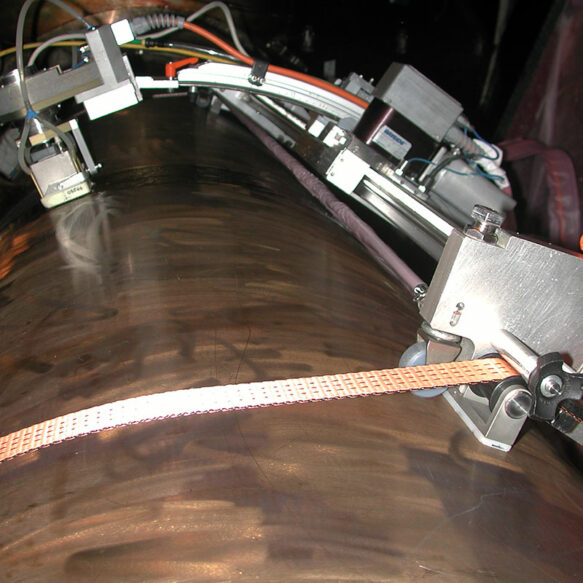

In addition to the inspection of pressure vessels and steam generator tubes, Intercontrôle’s operations also cover the inspection of pressure vessel heads and interiors, pressurisers and primary circuit piping.

Intercontrôle develops, qualifies and operates its inspection equipment on-site and provides the maintenance and logistics that are necessary to perform the inspections.

The list below contains details of the primary components we inspect.

100