About us

Intercontrôle, experience and expertise since 1974

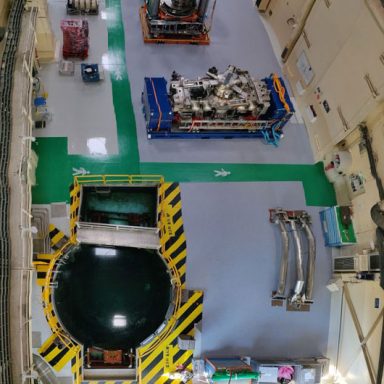

Intercontrôle inspects all the safety-critical components of the primary circuits in nuclear reactors by automated Non-Destructive Testing (NDT).

Intercontrôle has been a leader in this field of activity for more than 45 years.

Intercontrôle develops, qualifies and operates its inspection equipment on-site and provides the maintenance and logistics that are necessary to perform the inspections.

Intercontrôle is also a centre of excellence in Non Destructive Testing that can meet our own needs and the demands of our customers. Our broad range of activities demonstrates our expertise and our capacity to innovate.

Quality, safety and performance are the fundamental values of Intercontrôle, which is ISO 9001, OHSAS 18001 and CEFRI-E certified.

The organization of Intercontrôle

Intercontrôle’s governance is organized around the Management Committee placed under the authority of Guirec Maugat, CEO.

A team of experienced managers, responsible for operational and functional divisions, ensures the follow-up of the company’s strategy:

- Field Operations Department

- Technical and Projects Department

- Quality, Safety, Environment Department

- Sales & Business Development Department

- Human Resources Department

- Finance, Purchasing and General Facilities Department

Position in Framatome

Values

Our continuously maintained experience in the field of nuclear reactor inspections and our proven and recognized expertise enable us to offer reliable and innovative solutions in non-destructive testing. Our 330 employees are united in a light organization that is consistent with all of our activities, which allows us to better meet the expectations of all our customers. We are all invested around our core values: safety, quality and performance.

Guirec Maugat, Managing Director of Intercontrôle

References all over the world

Intercontrôle is active all over the world (France, Belgium, Sweden, Switzerland, United Kingdom, Finland, Slovenia, South Africa, China, etc.), in keeping with the various codes in use. More than 350 pressure vessels and more than 5 million steam generator tubes in pressurised water nuclear reactors have been inspected worldwide.

All the Non Destructive Testing (NDT) methods are used: standard and focused ultrasonics, mono and multi-frequency eddy current testing, radiography, Gammagraphy, 2D and 3D televisual examinations, penetrant testing, magnetic particle testing and thermography.

Some figures

Average Turnover : 60 M€

Inspections of reactor pressure vessels and steam generators represent 60% of the total volume of inspections

Intercontrôle employs 330 people, including 180 qualified operators, of whom 155 are COFREND certified (French non-destructive testing confederation) according to the European standard EN ISO 9712. They use our high-performance equipment and our advanced acquisition, analysis and data processing systems on site.

Our 100 specialised Research and Development engineers develop and industrialise NDT methods, software and automated systems, and they also develop and manufacture probes.

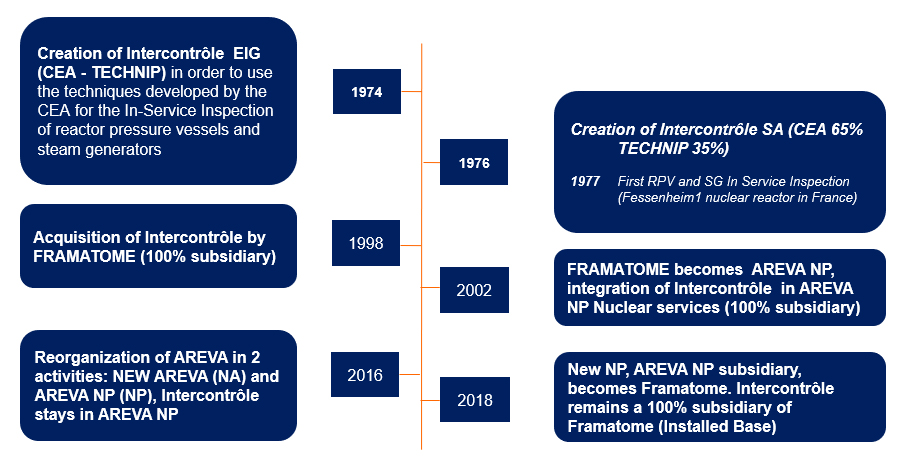

The history of Intercontrôle